- Home

- Company Tour

Raw material workshop

The housing of Sihai gearbox is made of aluminum alloy or cast iron with strong impact resistance, which are from famous international manufacturers,

Most of the parts are produced by our company under stringent quality control to obtain better compatibility.

Some important spare parts of our speed reducers, such as oil seal, lubricant and bearing, are from internationally renowned manufacturers. High quality raw materials and accessories guarantee the quality of our gearboxes from the source.

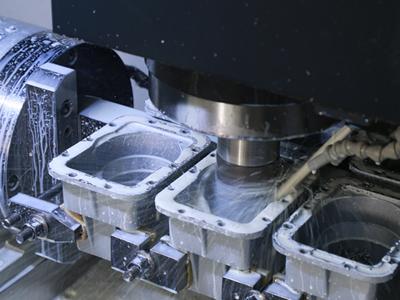

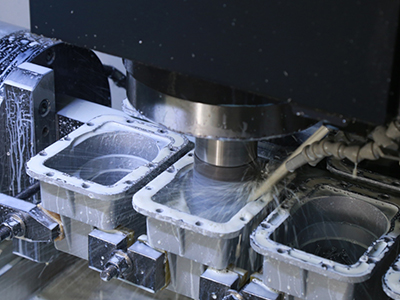

Processing workshopWith a workshop area of 16,000 m2, we also purchase a series of processing equipment like CNC lathes, CNC milling machines, CNC machining center, gear hobbing machine and gear grinding machine to guarantee machining precision and speed.

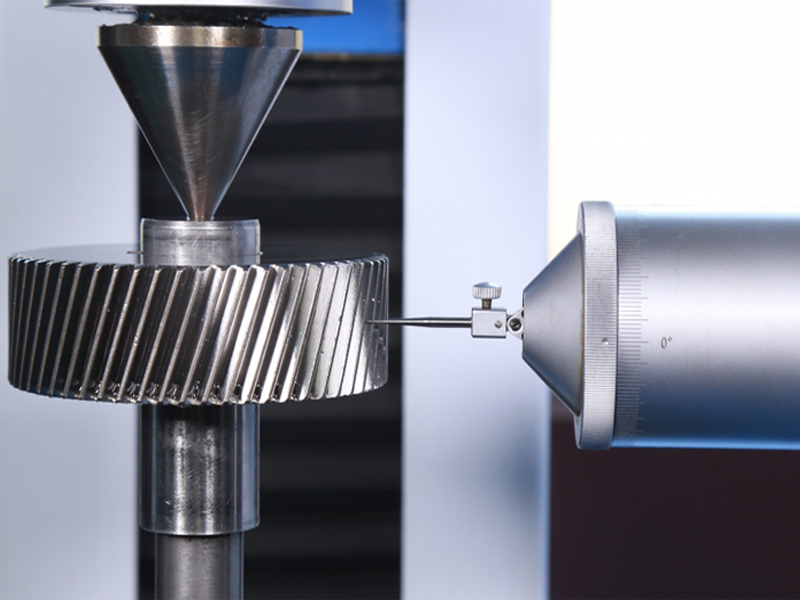

Rockwell hardness tester: to detect the hardness of gears and worms, which are qualified only when the hardness is abobe HRC58-62.

Roughness tester: to detect the roughness of gear, worm and oil seal.

Oil leak detector: to detect whether the finished reducer leaks oil by applying air pressure to the gearbox.

Bearing vibration measurer: to measure whether the vibration of the bearing is qualifies during rotation.

Spectrometer: to analyze elemental content of raw materials.